Capabilities

As our partner, you can be confident that your parts will arrive on-time and complete to print. Fairchild Auto-Mated Parts is an expert contract manufacturer that you can rely on for superior quality precision machined components through our Swiss turning and CNC milling/turning capabilities. We utilize advanced CNC machines to achieve tight tolerances and complex geometries, regardless of order volume.

Apart from our innovative capabilities, our customers continue to work with us because of the exceptional customer service we provide. We make the purchasing experience simple and ensure they’re satisfied with the parts we deliver.

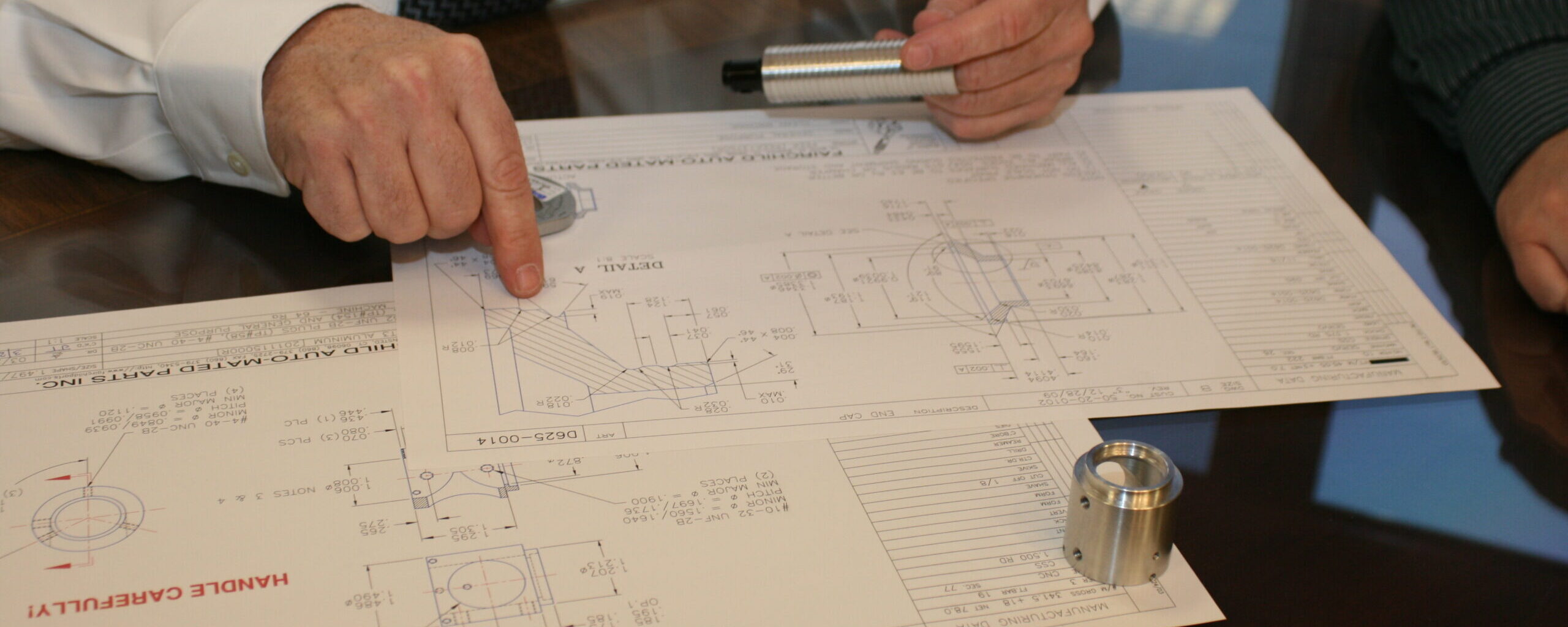

Manufacturing Planning

Before we begin with production, every project must undergo our manufacturing review stage. Our engineers use your drawing specifications to determine the best method and set of operations to manufacture your part complete to print. We then enter your order into our ERP system to track its progress throughout every operation until completion.

Benefits of manufacturing planning:

- Strong engineering background: Our engineers have decades of manufacturing experience, allowing them to efficiently assess your product for manufacturability, cost reduction opportunities, and potential risks.

- Thorough evaluation: We evaluate your part’s design requirements and specifications for manufacturability and notify you of any opportunities for improvement or potential risks during production.

- Robust manufacturing process: After evaluation, our engineers work with our production team to develop a manufacturing process that ensures your parts are made to print.

Our proficiency in job planning enables us to manufacture small to large scale precision machined components to meet or exceed our customer’s delivery schedule. Whether your projects need high volume Swiss turning solutions, complex CNC turning services, or large CNC milling operations, we’ll handle it all for you and deliver exactly what you need.

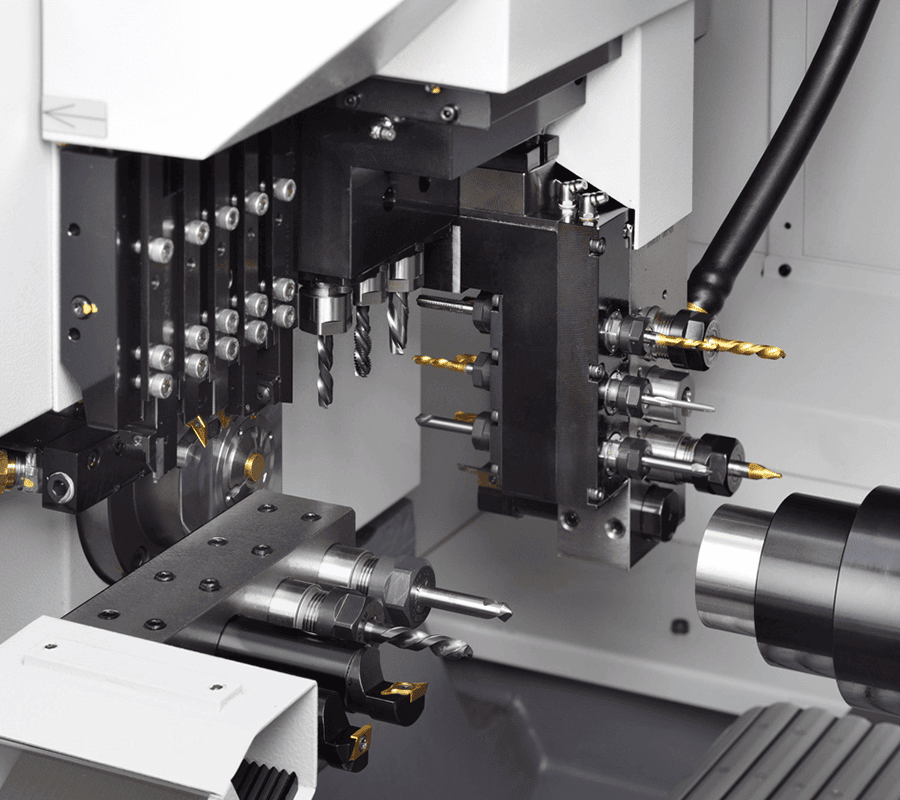

Swiss Turning

Swiss turning is a specialized style of lathe machining primarily for high volume small parts with tight tolerances. Rod bar stock up to 12ft in length are loaded into the machine by a barloader and positioned within the cutting envelope. The incredible speed that these machines operate at enables us to produce 10,000-100,000 parts in a short timeframe.

Benefits of Swiss turning:

- Ultra-tight tolerances: As the tolerances for our customer’s parts become tighter, Swiss turning has become the primary machining method to make a greater range of parts possible, all while maintaining the quality and reducing lead times.

- Simultaneous operations: Swiss turning is known for its ability to perform several machining operations at once which eliminates the need to use other machines to complete production. This reduces overall manufacturing time and reduces costs.

- Up to 7-axis machining capability: Our Swiss machines utilize up to 7-axes which increases the part complexity they can machine for more precision machined components primarily required by the aerospace and medical industries.

CNC Milling & Turning

Our CNC turning services and milling operations produce low volume, high complex parts that are generally larger in size compared to Swiss parts.

In our CNC turning services, raw material is held in place by a collet and rotated at high RPMs while cutting tools move within 3-axis space to machine the parts. On the other hand, in our CNC milling operations, large square or round materials are secured to a table within the machine while the cutting tools rotate at high RPMs and maneuver around the part to cut the desired part geometry.

Benefits of CNC milling and turning:

- High Complexity, Low Volume Jobs: Smaller jobs that require 100-1000 parts or even prototype parts that require additional attention are best suited for this department.

- Secondary Machining Operations: Our CNC turning services and milling operations allow us to finish any part that cannot be completed by our Swiss machines. This allows greater flexibility with the types of parts we can produce and helps with overall machining capacity.

- 3 & 8 axis Machining Capability: The outcome of having more axes means these machines can produce more complicated part geometries that are required in the aerospace, defense, and medical industries.

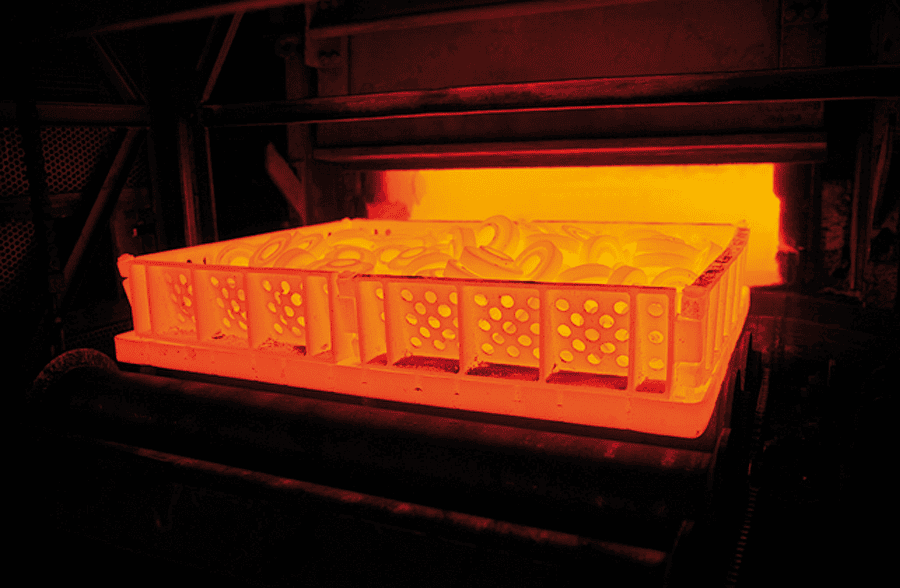

Value-Added Services

Fairchild Auto-Mated Parts works with trusted vendors that allow us to manage any specialized outside services that cannot be performed in-house for your precision machined components. We also offer in-house services to help customers reduce their costs and lead times.

Value-added services we offer include but are not limited to:

- Plating and passivation

- Electropolishing

- Heat treating

- Centerless Grinding

- Thread rolling

- Broaching

- Laser marking and stamping

- Testing

- Brazing

Included in-house services we offer:

- Mechanical assembly (as required)

- Deburring

- Parts cleaning

- Warehouse storage

- Special Packaging requirements

Customer Service

Apart from our expertise in precision machined components,, our dedicated staff ensure our customers always have a professional and easy purchasing experience with us. Our customers continue to choose Fairchilddue to the quality workmanship we have been delivering since 1944.

Benefits of choosing us as your manufacturer:

- Proactive and hands-on: We provide personal attention to our customer’s orders while establishing consistent and clear communication throughout the entire production process.

- Manufacturing Evaluation: Our team performs a thorough evaluation of your part’s requirements and develops a comprehensive manufacturing plan leveraging our ERP system to deliver your parts on time.

- Quality assurance: Our fully-staffed team follows our ISO 9001:2015 Quality Management System to meet industry quality standards.

- Accommodate customer requests: We’re fully prepared to work with our customers on special requests (packaging, inventory holds, expedites, First Article Inspections, etc.) to meet their specific needs.