Past Projects

Spotlights

We've machined precision parts for diverse industries such as aerospace, defense, medical, oil exploration, electrical hardware, HVAC systems, and high-end measuring devices. Every project is different and our team is prepared to handle any project with a complete understanding of our customers' requirements. Our past projects include:

Jeweler Hand Tools

Fairchild manufactures this delicate part from an aluminum extrusion supplied by customer. Special features include a .0005″ tolerance bore that receives a precision high speed bearing. The part is used in a high speed hand piece used by jewelers and dental technicians.

HVAC Valve Pieces

This two-piece assembly was designed by Fairchild’s engineers as part of a cost reduction program that resulted in significant savings for our. Fairchild makes both parts and then assembles them, providing a part that is ready for insertion into the valve body used in in HVAC control system.

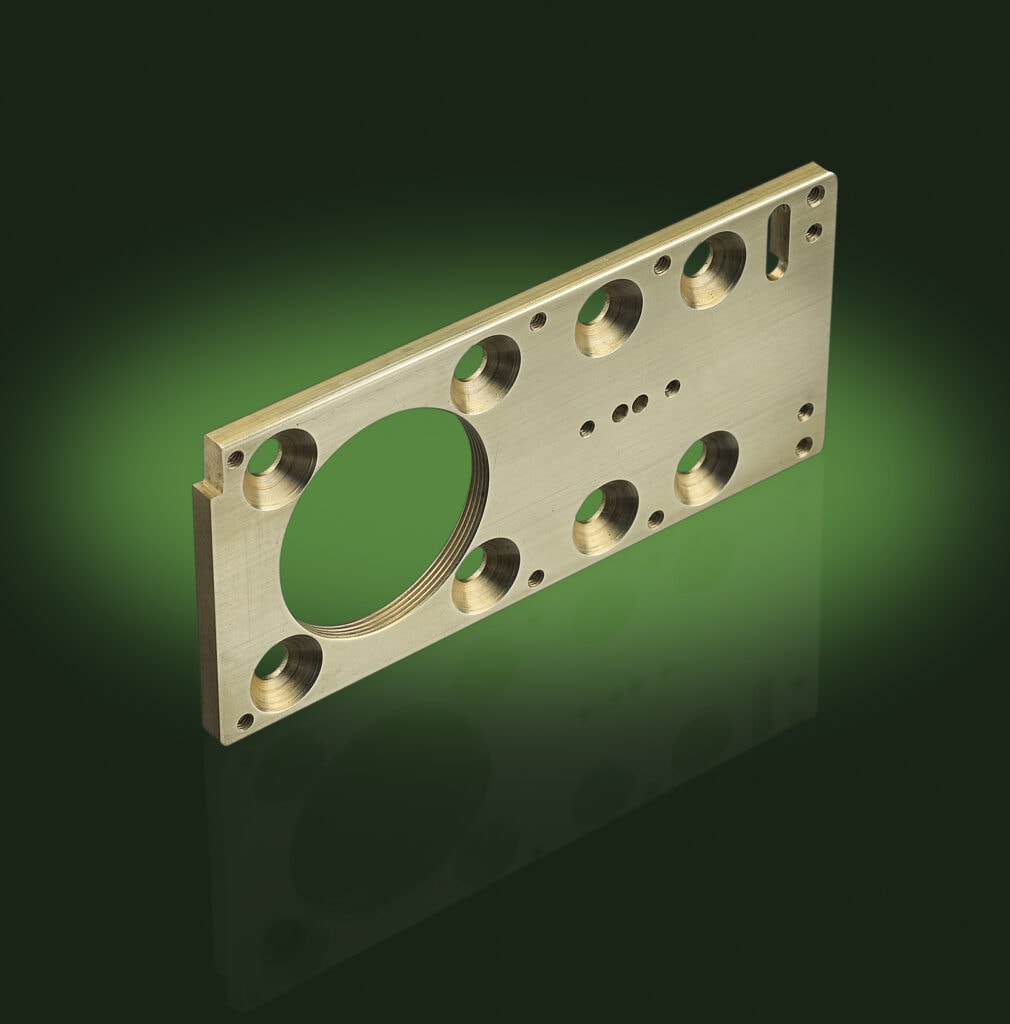

"Flat Work" Components

This part is an example of “flat work” machining performed on Fairchild’s high speed vertical machining centers.

Aerospace-Welded Components

Example of a two-piece welded assembly used in aerospace maintenance equipment.

Brass Valve Piston with O-Rings

Brass valve piston with added O-ring assembled and packaged and shipped complete to our customer.

Air Nozzle Assembly

This two-piece air nozzle assembly is used to direct inert gas during the repair and de-soldering of printed circuit boards components.

Stainless Steel with Finishes

This part is made from 303 stainless steel. The part is then annealed and electro polished to accentuate its appearance.

Phone Handset Cuffs

This part is made from CDA 330 brass tubing. It is part of a communications phone handset used on naval vessels.

Components with #00-120 Threads

Fairchild can produce small parts as well. These components are threaded with #00-120 threads and are produced in lot sizes of up to 75,000 pieces per run!

Radio Telescope Assembly

Special three-piece assembly of an adjusting mechanism for a large radio telescope.