Project Spotlight

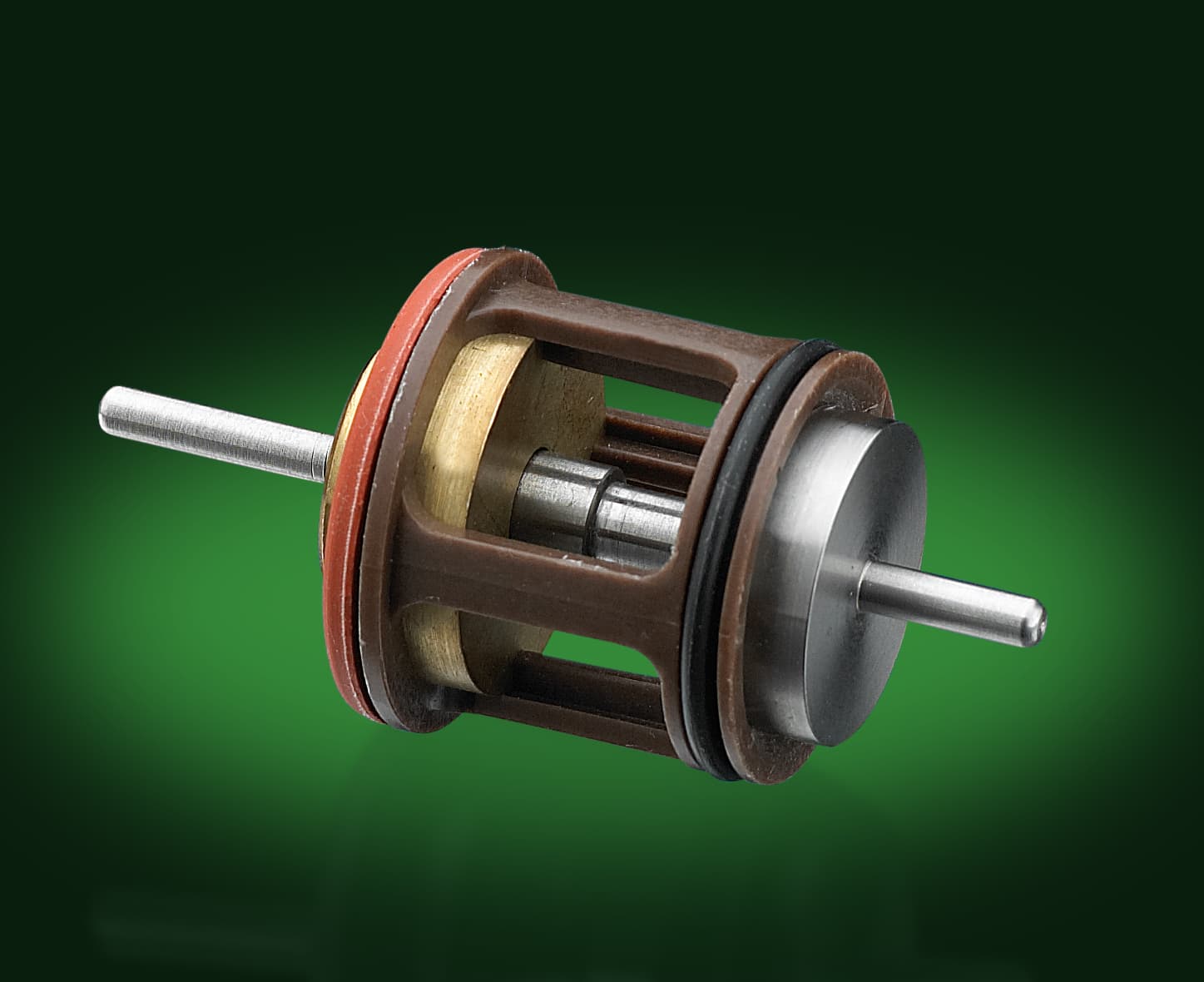

Fairchild Auto-Mated Parts built the above stainless steel and brass regulator shaft, used within a fluid control instrumentation mechanism, for the HVAC industry. To begin this process, we first proposed the unit to be manufactured as a two-piece assembled component, which would help reduce overall production costs. We then rough and finish turned both the shaft and top of each unit. Finally, we combined our CNC screw machining, press staking, and assembly operations to complete the shaft’s build.

Holding a ±.001″ overall tolerance, with a concentricity of .002″, a total run out of .001″, and a perpendicularity of .0012″, we built this part from a combination of T303 stainless steel and CDA 360 brass material. The shaft measured 1.300″ in length and .8228″ in outside diameter, and possessed a smooth, 32 RA finish. We also performed comprehensive inspections of all unit components, as well as checked the part’s final assembly for proper construction.

Due to the fact that we were able to manufacture these products to meet absolute client satisfaction, Fairchild Auto-Mated Parts presently manufactures 35,000 to 55,000 regulator shafts per year for this client, building these high-volume parts within a quick, 6-week turnaround time. These shafts are currently used in HVAC applications throughout the world.