Strengthen your supply chain with a precision manufacturing partner you can trust.

OVER 80 YEARS OF EXCELLENCE AND PRECISION

SCALE YOUR

PRODUCT LINE

WITH US

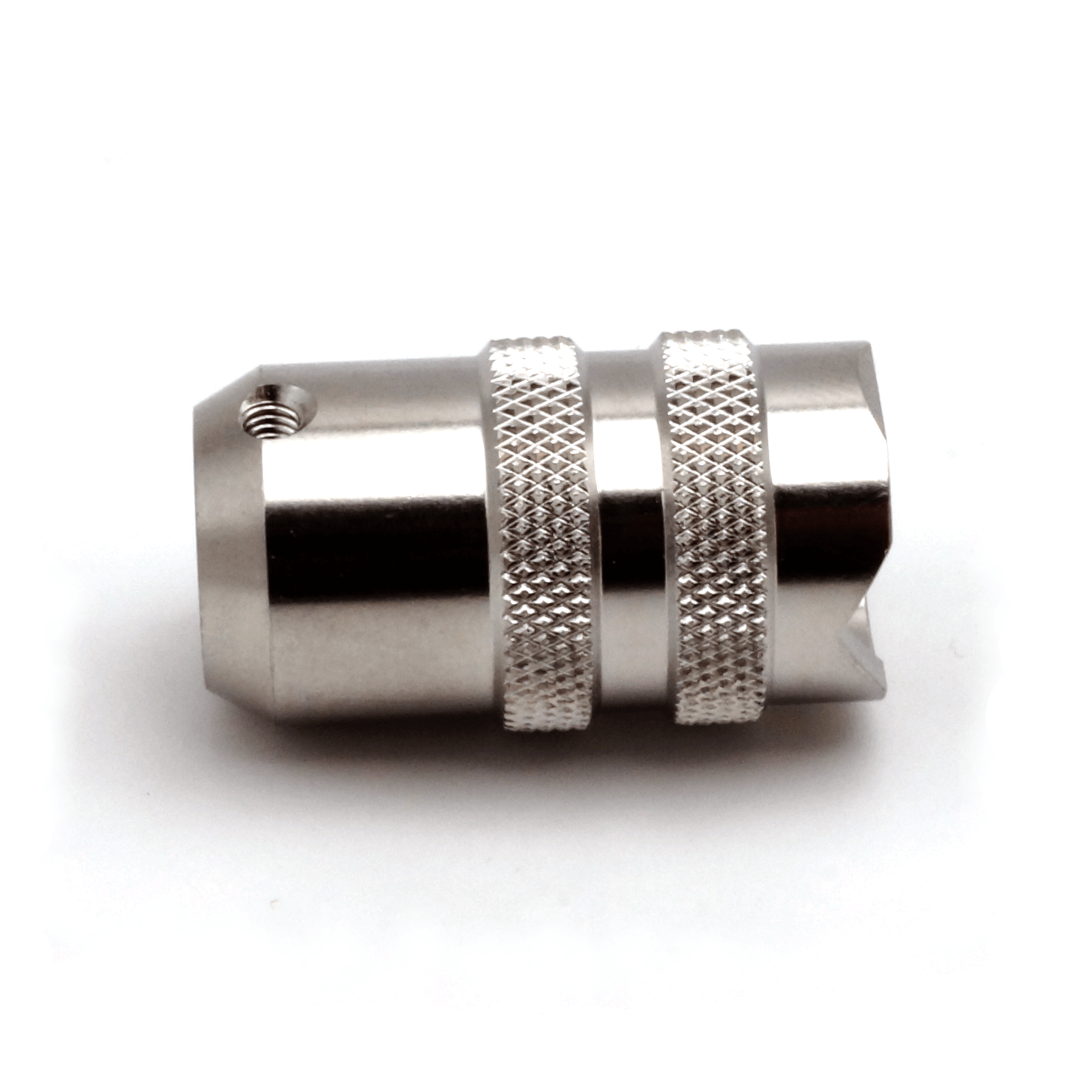

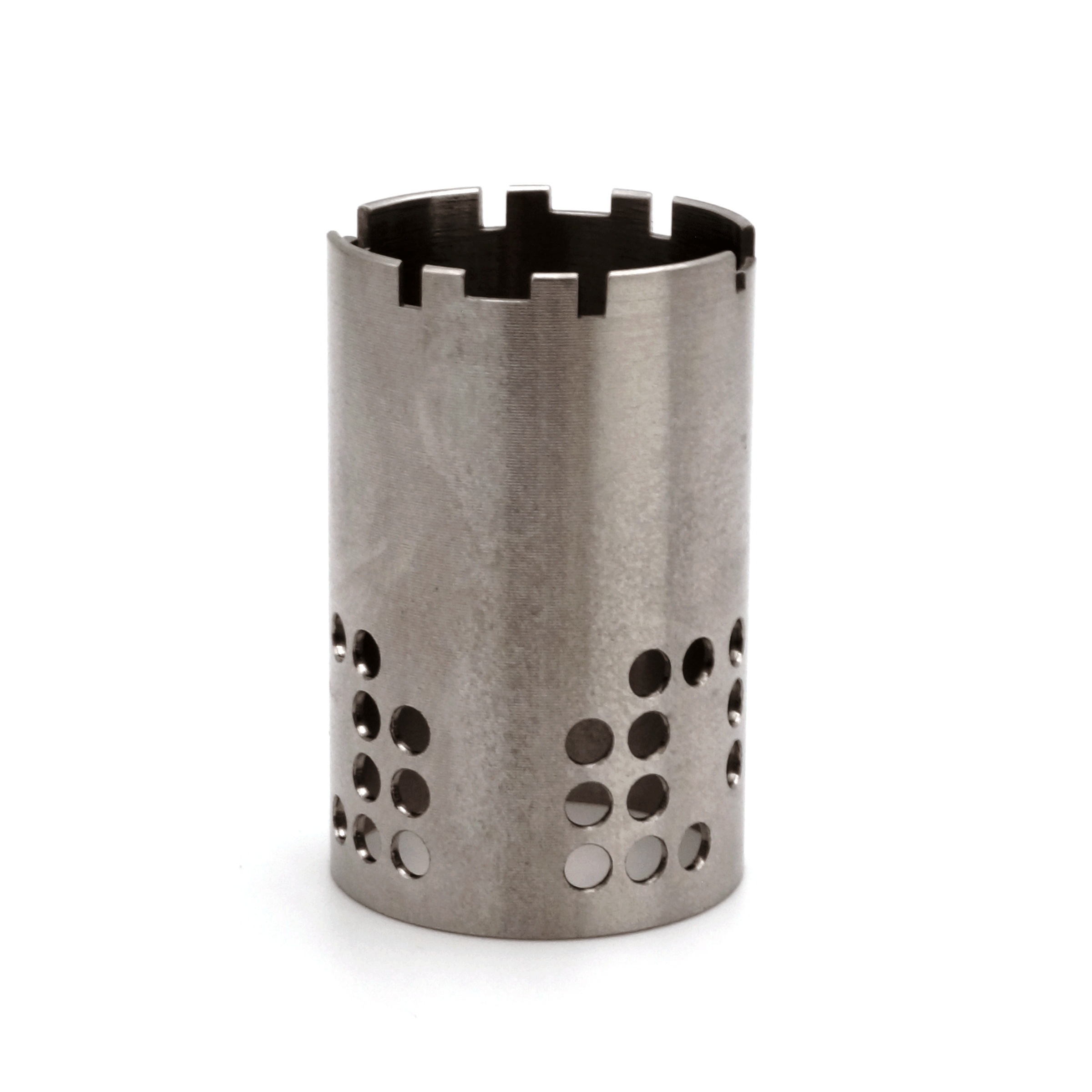

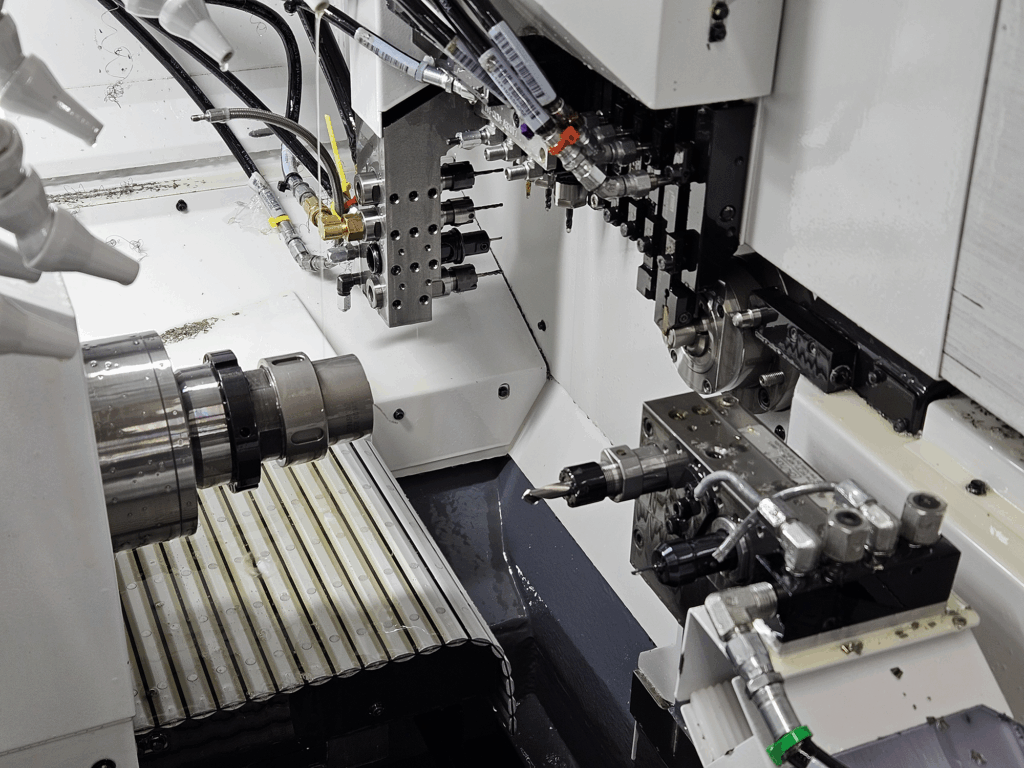

SWISS TURNING

Our Swiss turning capabilities deliver tight tolerances at high volumes—giving you consistent quality, faster lead times, and lower total cost.

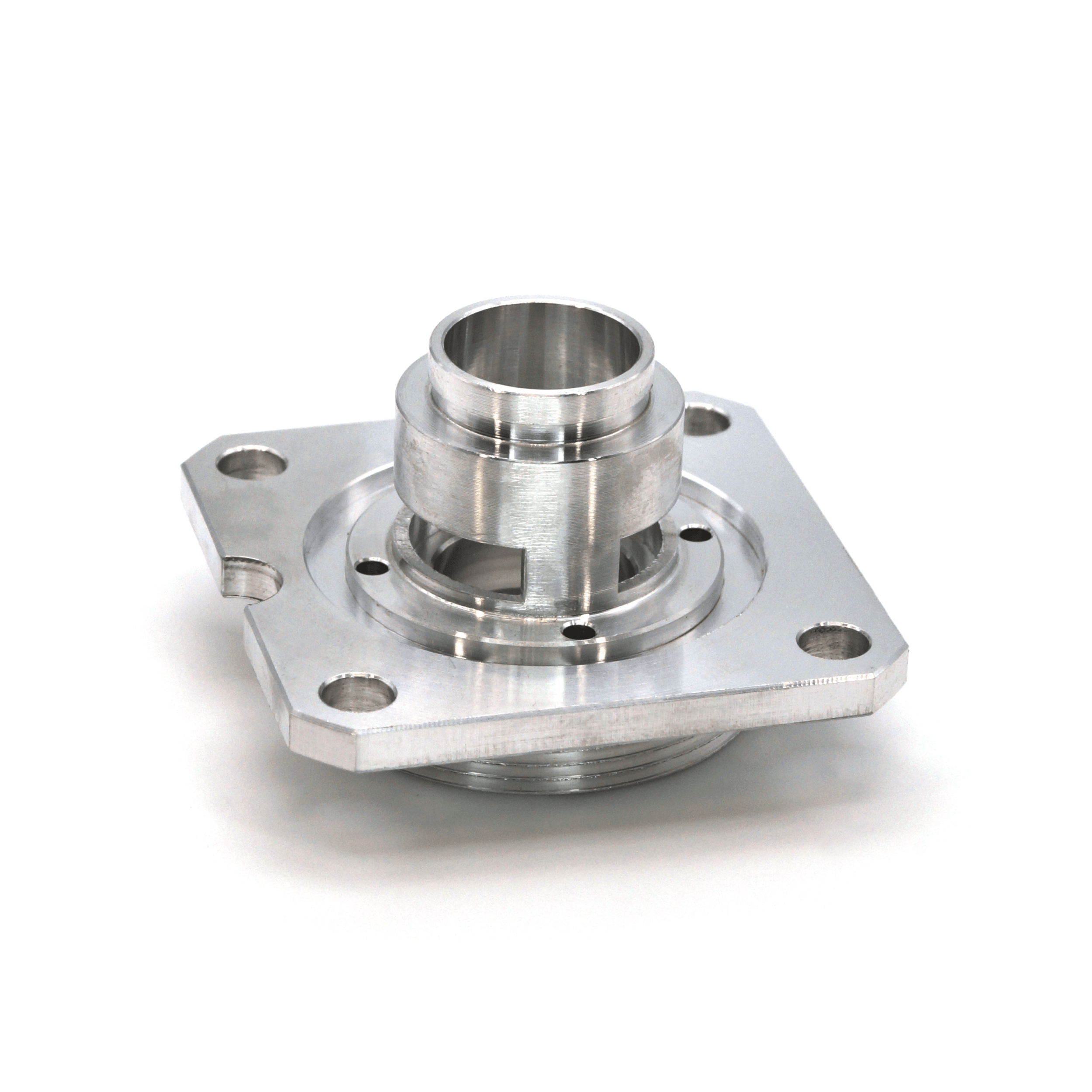

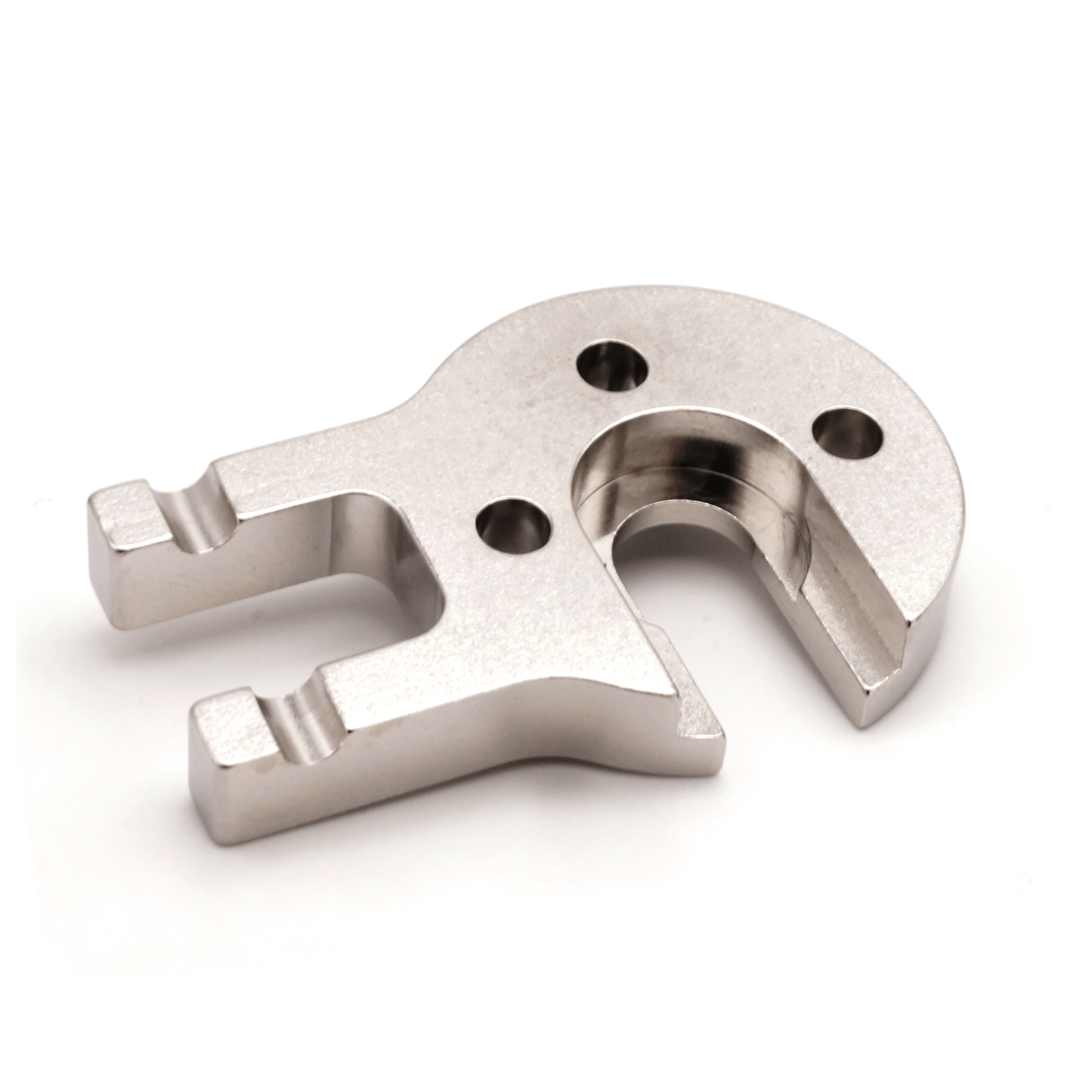

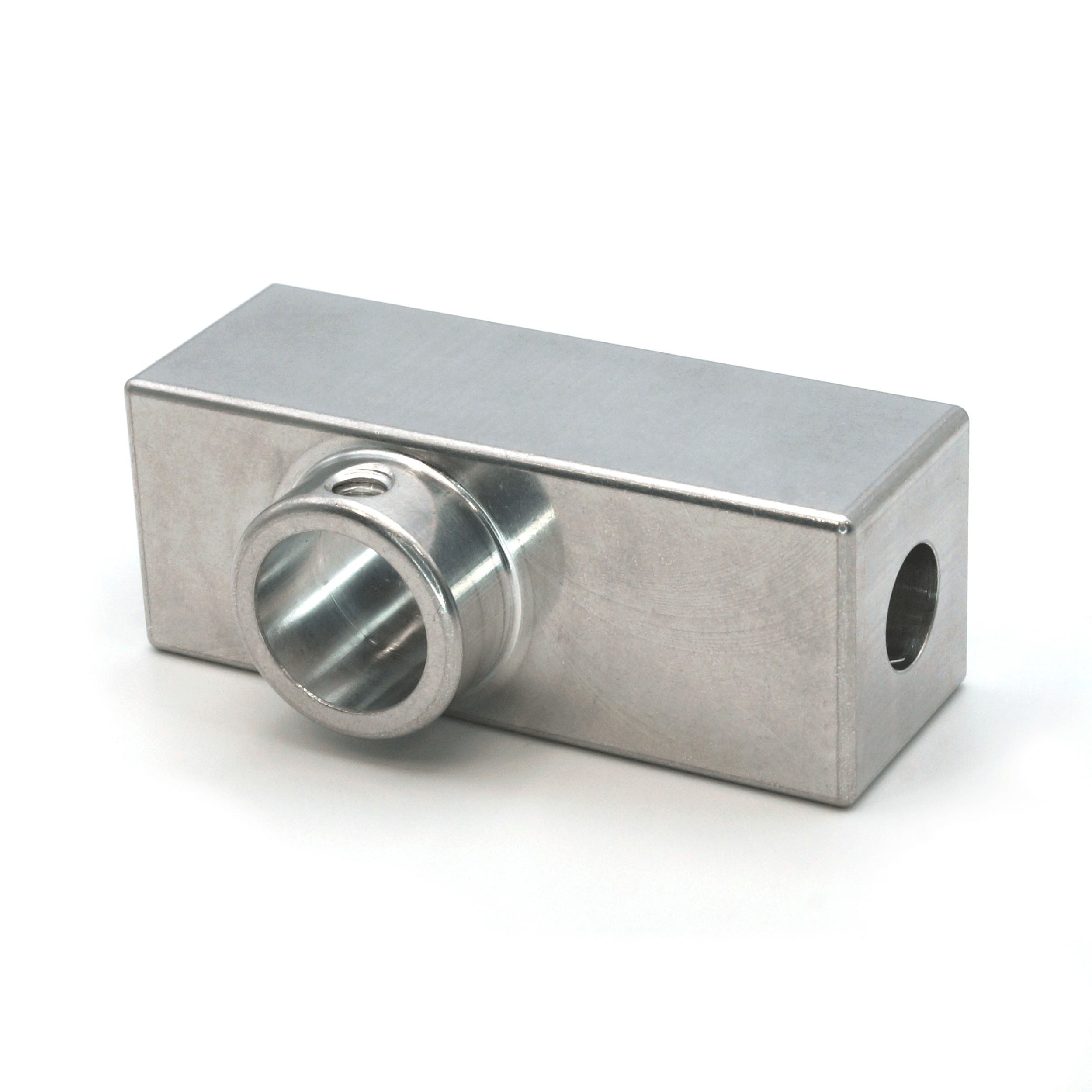

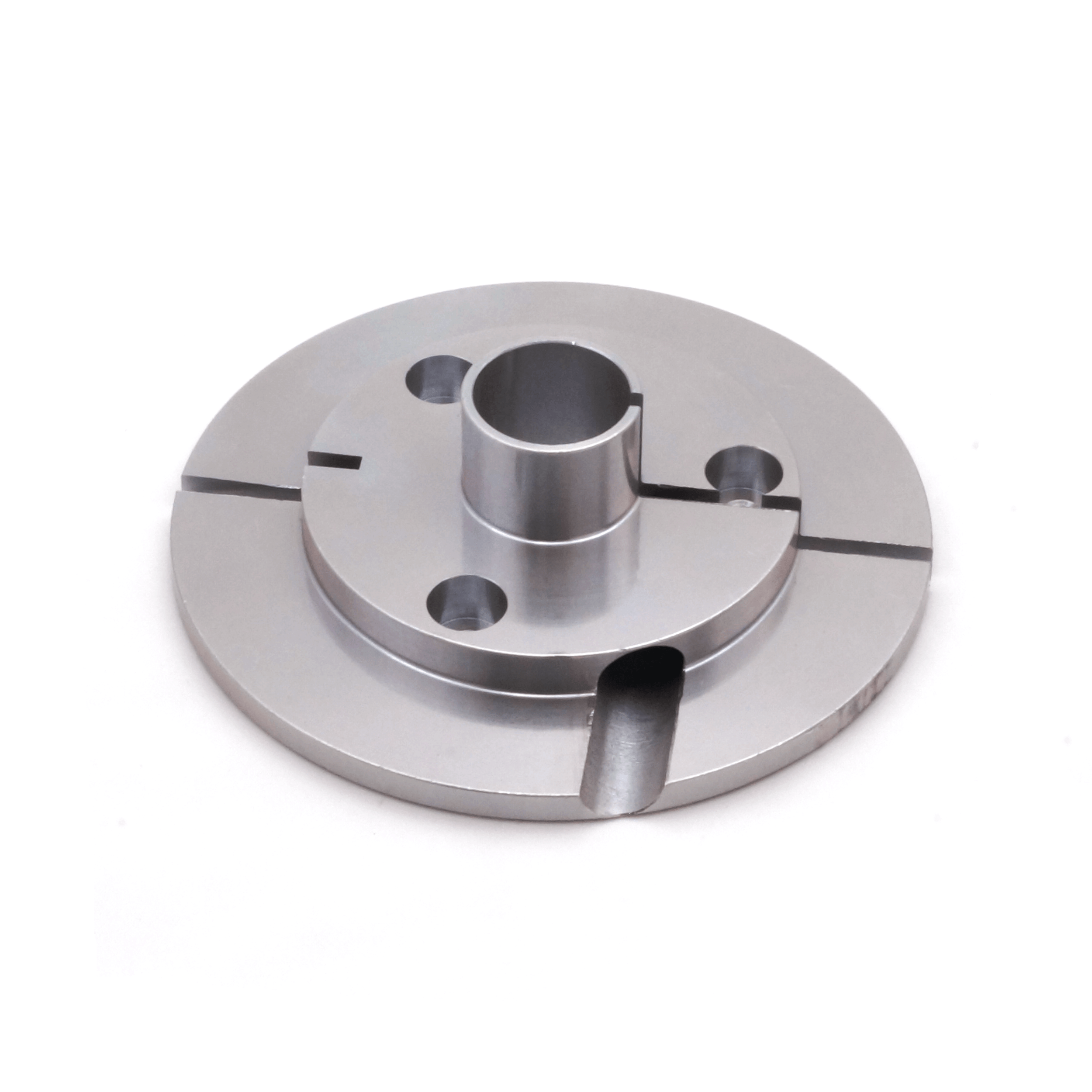

CNC TURNING & MILLING

Our CNC milling and turning capabilities produce complex geometries with tight-tolerance accuracy—machined to meet your most demanding specifications.

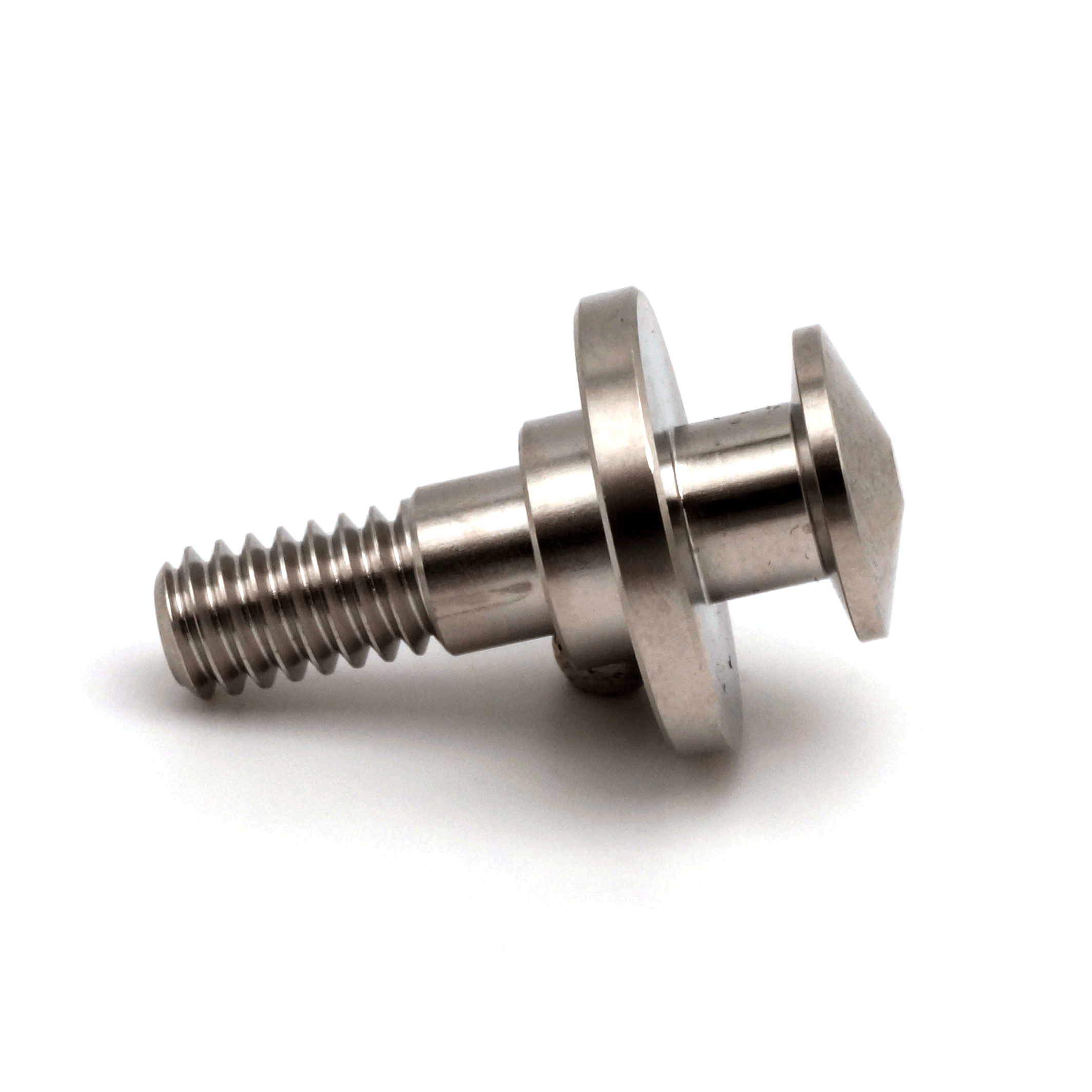

TURNKEY SERVICES

We handle sourcing, vetting, and coordinating all material and finishing vendors—ensuring your parts arrive complete to your specifications.

THE FAIRCHILD PROCESS

REQUEST A QUOTE

Send your technical drawing, desired quantities, and timeline, then we’ll get to work providing a thorough, customized quote.

PRODUCTION

After order acknowledgment, we start manufacturing your precision-machined parts complete to print.

DELIVERY

Your parts will be delivered on time, whether ordered in bulk or over a blanket period.

WHY CHOOSE

FAIRCHILD

- Tight Tolerances

Precision machining to tolerances of (±)0.0001″. - One-Stop-Shop

From qualified material suppliers to trusted finishing partners, we coordinate every step to deliver complete, ready-to-use components. - Proactive Customer Service

A professional purchasing experience driven by clarity, responsiveness, and follow-through. - Quality Assurance

With an AS9100D-certified QMS and thorough QA inspection, we deliver consistent, verifiable quality. - Continuous Improvement

We embrace continuous improvement, from advanced machining technology to streamlined digital systems, all to enhance our performance and elevate your experience.