Case Study: Precision Aluminum Aircraft Fittings

Aircraft fittings are necessary for securing and connecting different parts of the aircraft. Because aerospace operations need to be failure-free, aircraft fittings need to be made with high-quality materials. Aluminum is one of the best materials for aerospace fittings because of its impressive strength-to-weight ratio, corrosion resistance, and ease of fabrication.

The following case study demonstrates how we approached a specific project where a client requested custom aluminum aircraft fittings.

The Challenge

A client approached us for custom aluminum aircraft fittings. The challenge was that they had a variety of features, dimensions, and tolerances that were fairly complex and unique. However, due to our long history of producing parts of this nature, the client had confidence in our ability to deliver quality parts on time and at an affordable price.

The Process

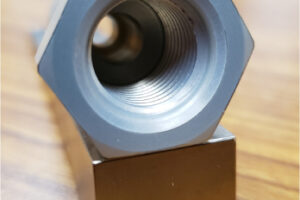

We began by using the customer-supplied specifications for manufacturing the aluminum aircraft fittings. The overall part dimensions were 1.870” in length and 0.675” in diameter, with the tightest tolerance being ±0.001”.

Using our Miyano BNX-42SY CNC 5-Axis Turning Center, we commenced fabrication, which involved these processes:

- Face off

- Turning

- Milling

- Spot drilling

- Boring

- OD grooving

- OD/ID threading

The tight tolerances and many complex features of these parts meant that we had to carefully plan each stage so that we could perform all fabrication processes on one machine rather than splitting them up over multiple machines.

Once the pieces were machined, they were hand-deburred, finished at 63 Ra or better, and anodized to protect them from corrosion and wear. We also conducted first article inspection, in-process inspection, and final inspection to ensure that the dimensions and parts met the required specifications for the aerospace fittings.

The Result

The initial turnaround time for the order was three weeks, and the customer was pleased with the on-time delivery of their requested parts. The client continues to place orders with us for this part, with 150 pieces per order. We also make other parts for them, which boosts their confidence in us to deliver quality products of any kind.

High-Quality Machined Parts for the Aerospace Industry

Manufacturing aerospace fittings requires high precision levels and skilled manufacturing techniques. As a leading supplier of machined parts for the aerospace industry, Fairchild Precision Parts understands the importance of quality and reliability.

With almost 80 years of industry experience, we have the expertise to manufacture custom aluminum aircraft fittings that satisfy the unique needs of our clients. Our quality control team ensures that all components delivered meet the required aerospace specifications for safety and reliability. Our state-of-the-art equipment includes CNC Swiss screw machining centers, turning centers, milling centers, and more.

Contact us today to get precision machined parts for your aerospace project.