At Fairchild Precision Parts, we specialize in high-precision Swiss-turned components designed for performance, consistency, and scale. We’re not a transactional job shop. We are a long-term production partner for companies that need reliable, repeatable manufacturing at higher volumes. If you’re looking for a machining partner who understands tolerance control, process capability, and sustained growth —…

Gearing Up for 2026: Building Momentum & Looking Ahead

The momentum we’ve built is real and we’re carrying it straight into the new year with focus, confidence, and excitement. We’re starting 2026 strong, with a solid backlog, sharpened processes, and a clear vision for what comes next. Manufacturing continues to evolve rapidly, and staying ahead means not only reacting to change, but anticipating it….

Reflecting on 2025: A Year of Precision, Progress, and People

As we wrap up 2025, we’re taking a moment to reflect on what has been an exceptional year at Fairchild Precision Parts. The results speak for themselves—but more importantly, they tell the story of a team that is deeply committed to quality, accountability, and continuous improvement. This year, together, we achieved: 99.96% defect-free quality Over…

Manufacturing Month: Why American Manufacturing Matters More Than Ever

October marks Manufacturing Month, a time to shine a spotlight on the industry that builds America from the ground up. From the planes that defend our skies to the medical devices that save lives, manufacturing drives the nation’s innovation, employment, and economic stability. At Fairchild Precision Parts, we’re proud to be part of this…

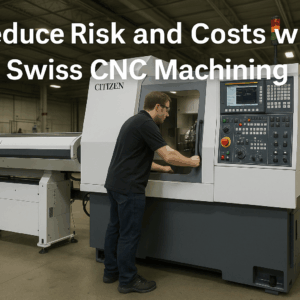

5 Ways Swiss CNC Turning De-Risks Your Supply Chain (and Lowers Total Cost)

When you’re building mission-critical systems, variability is the enemy. Missed tolerances, late deliveries, or incomplete documentation can ripple through schedules and budgets. That’s why engineering and sourcing teams increasingly standardize on partners who specialize in high-volume, high-precision Swiss CNC turning. At Fairchild Precision Parts, we’ve spent more than 80 years helping aerospace, defense, medical,…

The New Frontier of Precision Machining: 5 Manufacturing Trends Shaping 2025 and Beyond

In the world of precision CNC machining, staying ahead isn’t just about tighter tolerances or faster spindle speeds. The industry is evolving at a rapid pace, and the most successful machine shops of tomorrow will be those that adapt to—and drive—these shifts. Below are five major trends transforming manufacturing today, and how Fairchild is positioning…

Swiss Machining vs. Traditional CNC: Understanding the Key Differences

When selecting the ideal manufacturing approach for precision components, understanding the fundamental differences between Swiss CNC machining and traditional CNC methods can significantly impact the success of your project. Swiss machining represents a specialized precision manufacturing technique that excels in producing high-volume, small-diameter parts with exceptional accuracy. Meanwhile, traditional CNC machining offers versatility for larger…

The Role of CNC Machining in High-Precision Manufacturing

At Fairchild Precision Parts, we’ve seen firsthand how advanced machining technology can transform raw materials into precisely crafted components. Our team has spent years refining processes that help clients reduce costs and meet rigorous quality and schedule demands. From small-volume, intricate parts to larger-scale production, CNC machining is at the heart of our success. An…