High-Precision Swiss Turning

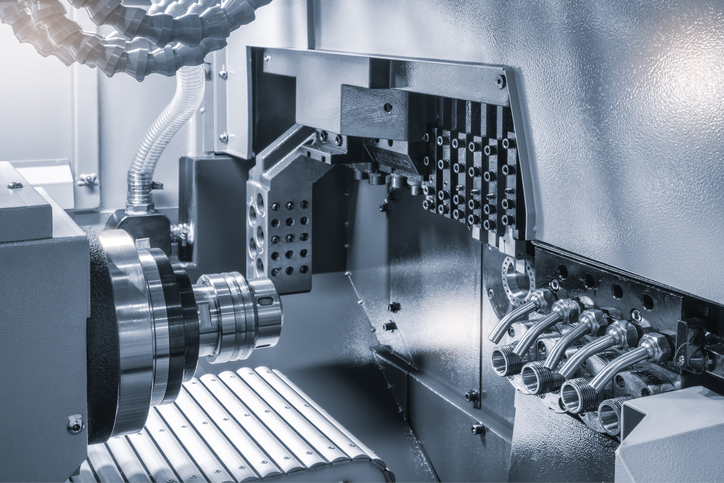

Fairchild Precision Parts delivers high-precision Swiss CNC machining for aerospace, defense, medical, and industrial manufacturing. Our advanced Citizen Swiss-type CNC lathes produce complex, tight-tolerance parts with (±)0.0001″ accuracy, consistent quality, and fast cycle times.

Swiss CNC Machining Capabilities

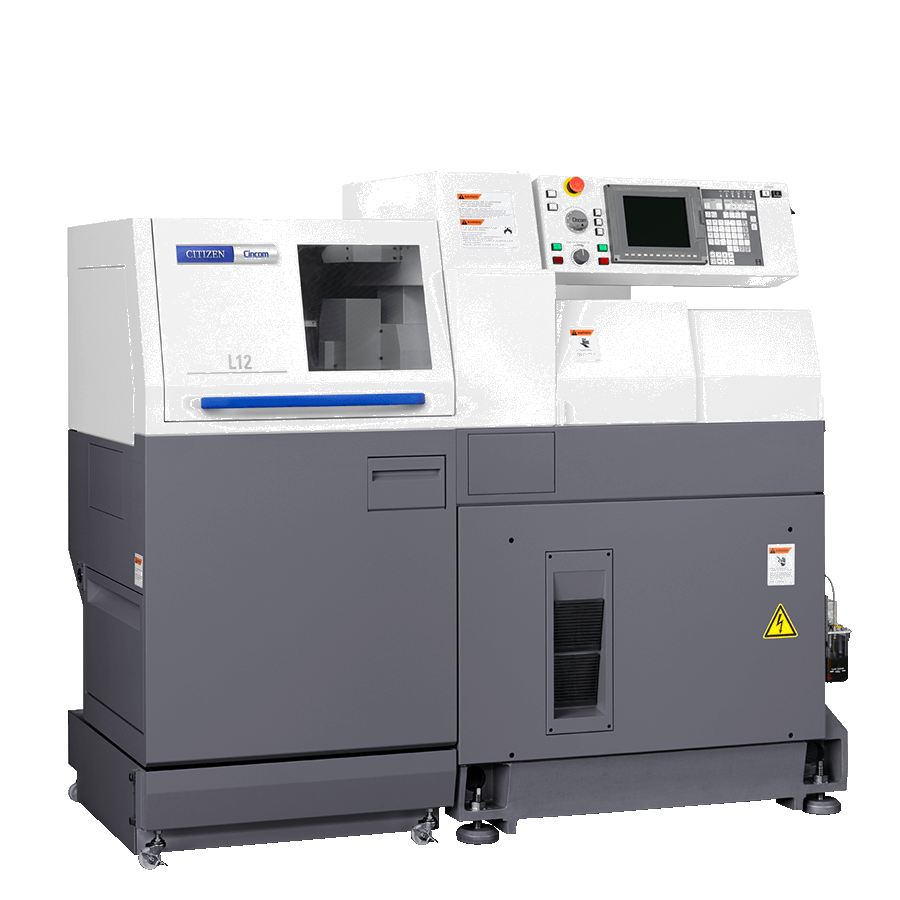

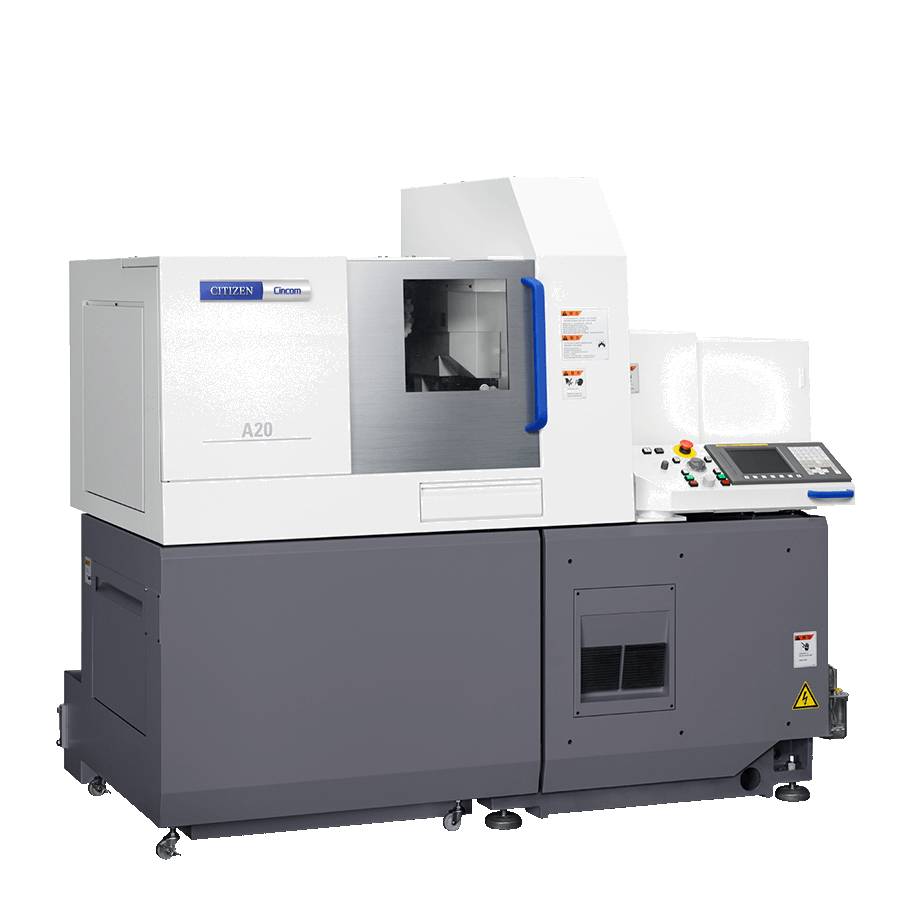

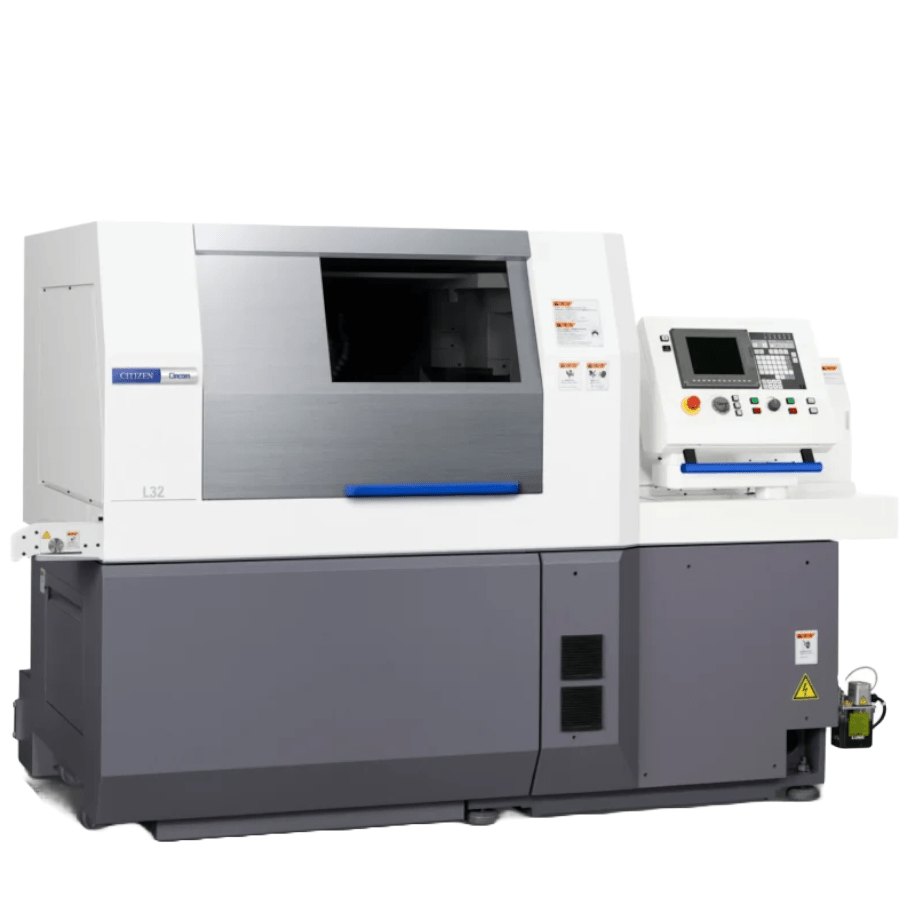

Advanced Citizen Swiss CNC Lathes

- Bar capacity: 3/32″ to 1-1/4″ diameter

- Production volumes: 100 to 100,000 pieces

- Equipment features: C-axis, live tooling, automatic magazine bar feeders, high-pressure coolant

- Operations: Turning, milling, threading, tapping, slotting

Materials We Machine: Stainless steel, aluminum, brass, bronze, titanium, steel, copper, nickel, engineering plastics, and exotic alloys