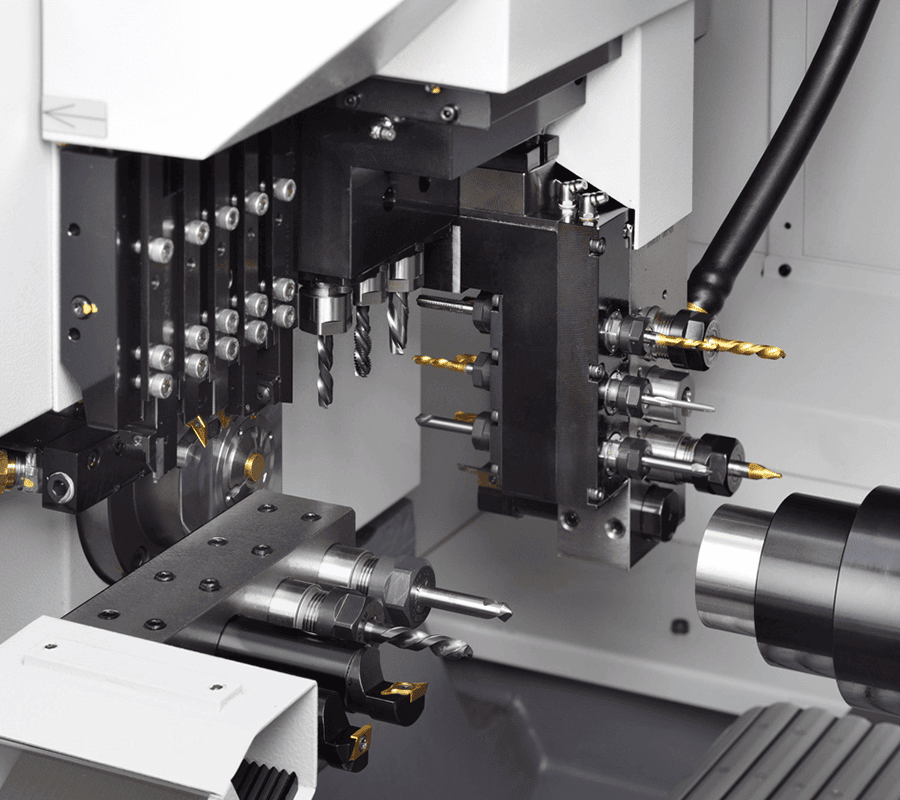

EXPERTS IN PRECISION MACHINING

Since 1944, Fairchild Precision Parts has been manufacturing precision machined parts for North American companies, becoming an integral part of the supply chain for many industry-leading manufacturers. We partner with our customers, managing their project from material sourcing to parts finishing and finding ways to make their parts costs less.